Motor swaps are one of the immortal customs of hot rodding. Possibly it's dropping in a smallblock to supplant that six-banger, on the other hand huge piece of a Mouse. There's various this-forthat mixes out there and one of the more famous ones is introducing a cutting edge LS motor into a exemplary Chevy.

Motor swaps are one of the immortal customs of hot rodding. Possibly it's dropping in a smallblock to supplant that six-banger, on the other hand huge piece of a Mouse. There's various this-forthat mixes out there and one of the more famous ones is introducing a cutting edge LS motor into a exemplary Chevy.

Heading off to a present day powerplant has a few points of interest. The aluminum is much lighter than the iron utilized as a part of prior motors, the EFI framework will most definitely net better fuel economy, the self-tuning nature of the motor's PC framework adds to driveability, also, LS motors make genuine force for their removal.

Definitely, they are a bit tested in the looks division contrasted with Gen I little and enormous squares; be that as it may, if your objective is to make an auto amusing to drive, they are difficult to beat.

LS swaps have been continuing for more than 15 years presently, so it's a considerable measure less demanding than it was in the early days to shoehorn one in. In any case, there're still a couple of little obstacles to jump. The EFI framework has specific needs and since everything is PC controlled there's a considerable measure of wiring to wrangle.

On account of the post-retail, the entire introduce process has transformed into, generally, a fitting and-play bargain.

The five key zones for a LS swap are: the fuel framework, headers, motor mounts, oil skillet, and gadgets. A few individuals would include cooling in there, in any case, in truth, a LS motor couldn't care less about the radiator insofar as it has adequate cooling limit.

A LS motor will even mate up with oldschool programmed transmissions, in any case, it truly sparkles at the point when joined with one of the more up to date PC controlled overdrive transmissions, both as far as execution furthermore, economy.

In any case you choose to go, there's in all likelihood a secondary selling prepared to-go arrangement accessible, which beyond any doubt beats the days of yore of having to MacGyver everything.

For this introduce we had a 1967 Chevelle with an all-iron huge square motor upheld by a TH400 trans.

It sounded extraordinary, yet the gas mileage was horrendous what's more, to be completely forthright, it truly wasn't that quick or enjoyable to drive. The proprietor truly needed a pleasant driver what's more, as it might have been, his drives for the most part comprised of going from one corner store to the following. Given the greater part of this, we thought his ride would be a cool contender for an infusion of somewhere in the range of 21st century inno.

Before uprooting the tired huge square we measured the Chevelle and thought of 3,680 pounds with 57 percent of the weight over the front tires. We're certain the LS will spare us weight, however we were interested in the matter of what amount.

This Chevrolet Performance case motor is the 6.2L (that is 376 cubic inches for those that don't move with the metric framework) LS3 (PN 19301326). Appraised by GM at a moderate 430 pull, it comes complete from the fuel injectors on the composite admission to the curl packs and oil skillet. At a road cost of under $6,000, it's not shabby, but rather when you think of it as' an all-aluminum EFI-sustained LS then it's positively an awesome value for-the-money.

This Chevrolet Performance case motor is the 6.2L (that is 376 cubic inches for those that don't move with the metric framework) LS3 (PN 19301326). Appraised by GM at a moderate 430 pull, it comes complete from the fuel injectors on the composite admission to the curl packs and oil skillet. At a road cost of under $6,000, it's not shabby, but rather when you think of it as' an all-aluminum EFI-sustained LS then it's positively an awesome value for-the-money. We needed more power, however we would not like to tear separated a fresh out of the box new motor. The arrangement was to hurl in a somewhat greater camshaft from the people over at COMP. For this situation we ran with at 222/234 duration,0.566/0.576 lift, 113 LSA cam (PN 146-426-11) that wouldn't require new valvesprings.

We needed more power, however we would not like to tear separated a fresh out of the box new motor. The arrangement was to hurl in a somewhat greater camshaft from the people over at COMP. For this situation we ran with at 222/234 duration,0.566/0.576 lift, 113 LSA cam (PN 146-426-11) that wouldn't require new valvesprings. To spruce up the LS motor a bit we swapped over to a set of dark Holley valve covers (PN 241-91). They're an extraordinary value for-the-money choice and help to clean up the motor a bit. We likewise flipped the fuel rail around so the delta was on the traveler side and utilized an Earl's connector fitting (PN 991966ERL) to change over our GM push-lock to a - 6AN fitting.

To spruce up the LS motor a bit we swapped over to a set of dark Holley valve covers (PN 241-91). They're an extraordinary value for-the-money choice and help to clean up the motor a bit. We likewise flipped the fuel rail around so the delta was on the traveler side and utilized an Earl's connector fitting (PN 991966ERL) to change over our GM push-lock to a - 6AN fitting. The case motor came to us with a fifth-gen Camaro oil container, which is fine for another Camaro, however far too huge for most swaps. To comprehend this, we got one of Holley's recently upgraded container (PN 302-2), which has a shallow front area for additional crossmember free

The case motor came to us with a fifth-gen Camaro oil container, which is fine for another Camaro, however far too huge for most swaps. To comprehend this, we got one of Holley's recently upgraded container (PN 302-2), which has a shallow front area for additional crossmember free We were doing this introduce over at Stoker's Hot Rod Factory what's more, David Stoker had these sweet LS motor mount plates he created. The decent part of this configuration is that it permits the motor to slide forward and back to nail down just the right position.

We were doing this introduce over at Stoker's Hot Rod Factory what's more, David Stoker had these sweet LS motor mount plates he created. The decent part of this configuration is that it permits the motor to slide forward and back to nail down just the right position. With the motor all sorted out, the time had come to get it into the 1967 Chevelle. Instead of jolt the transmission to the motor and take a stab at dropping it in as one huge get together we selected rather to introduce the motor first. This let us more effectively utilize the opened motor mount plates to get the motor in simply the right spot.

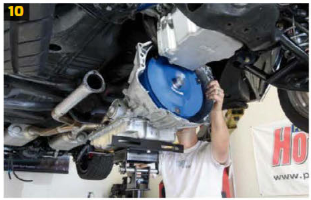

With the motor all sorted out, the time had come to get it into the 1967 Chevelle. Instead of jolt the transmission to the motor and take a stab at dropping it in as one huge get together we selected rather to introduce the motor first. This let us more effectively utilize the opened motor mount plates to get the motor in simply the right spot. We poured some fluid in the Chevrolet Performance torque converter (PN 19299802) and mated it to the 4L65E transmission. With that done we raised it under the Chevelle. We did find that a few "clearancing" of the passage with a sledge was required, yet not a ton.

We poured some fluid in the Chevrolet Performance torque converter (PN 19299802) and mated it to the 4L65E transmission. With that done we raised it under the Chevelle. We did find that a few "clearancing" of the passage with a sledge was required, yet not a ton. Rather than spending money on another transmission crossmember, we could reuse the stock one by removing the additional mounting tabs and marginally repositioning it on the Chevelle's manufacturing plant outline.

Rather than spending money on another transmission crossmember, we could reuse the stock one by removing the additional mounting tabs and marginally repositioning it on the Chevelle's manufacturing plant outline. Indeed, even the once-complex undertaking of wiring up a LS motor is presently a fitting and-play bargain, particularly in case you're utilizing a Chevrolet Performance box motor. This unit (PN 19258270) incorporated the controller, motor bridle, mass air flow meter, MAF mounting manager, oxygen sensors, throttle-by-wire pedal get together, and sensor mounting manager.

Indeed, even the once-complex undertaking of wiring up a LS motor is presently a fitting and-play bargain, particularly in case you're utilizing a Chevrolet Performance box motor. This unit (PN 19258270) incorporated the controller, motor bridle, mass air flow meter, MAF mounting manager, oxygen sensors, throttle-by-wire pedal get together, and sensor mounting manager. This front embellishment pack from Chevrolet Performance fit the bill flawlessly. It incorporates a 150-amp alternator, power guiding pump, and every one of the sections, tensioners, and belts required. Chevrolet Performance offers a unit with an A/C compressor, yet it's not good with generally post-retail frameworks, for example, Vintage Air.

This front embellishment pack from Chevrolet Performance fit the bill flawlessly. It incorporates a 150-amp alternator, power guiding pump, and every one of the sections, tensioners, and belts required. Chevrolet Performance offers a unit with an A/C compressor, yet it's not good with generally post-retail frameworks, for example, Vintage Air. Our Chevelle as of now had a Vintage Air framework, so our next test was finding an approach to mate the Sanden compressor, in the right position, with the Chevrolet Execution pulley framework. The answer was this compressor section from Holley Performance (PN 20-134).

Our Chevelle as of now had a Vintage Air framework, so our next test was finding an approach to mate the Sanden compressor, in the right position, with the Chevrolet Execution pulley framework. The answer was this compressor section from Holley Performance (PN 20-134). The Holley section found the Sanden compressor high on the traveler side of the motor, which is precisely where we needed it. The cast-aluminum section likewise coordinated well with the Chevrolet parts.

The Holley section found the Sanden compressor high on the traveler side of the motor, which is precisely where we needed it. The cast-aluminum section likewise coordinated well with the Chevrolet parts. Hoses are dependably somewhat of a test, however in the wake of burrowing around our nearby parts store we discovered two that would work. For the upper we utilized part number D71852 and for the lower C70391, both from Carquest.

Hoses are dependably somewhat of a test, however in the wake of burrowing around our nearby parts store we discovered two that would work. For the upper we utilized part number D71852 and for the lower C70391, both from Carquest. We utilized the Chevelle's current radiator, so it didn't have the custom setup with both the bay and outlet on the right. This made running an air admission testing following the upper hose blocked setting off to one side and the Optima battery blocked going extremely far to one side. For the present we utilized an aluminum 90-degree elbow and a short tube (with the MAF bung introduced) with a Specter Performance air filter (PN 8131) to get us by. Later, we may swap radiators or migrate the Optima battery so we can get the filter more distant far from motor war.

We utilized the Chevelle's current radiator, so it didn't have the custom setup with both the bay and outlet on the right. This made running an air admission testing following the upper hose blocked setting off to one side and the Optima battery blocked going extremely far to one side. For the present we utilized an aluminum 90-degree elbow and a short tube (with the MAF bung introduced) with a Specter Performance air filter (PN 8131) to get us by. Later, we may swap radiators or migrate the Optima battery so we can get the filter more distant far from motor war. LS motors, and EFI motors when all is said in done, have exceptionally specific fuel needs. It's anything but difficult to overcomplicate things, however we chosen to keep it basic. The principle player in our EFI fuel framework is this tank from Tanks Inc. (PN TM37B-T). It's inside perplexed and 1-inch more profound for expanded limit. The steel tank is electrifies and afterward powdercoated silver. The tank utilized Tank Inc's. high-flow (255-lph) submerged pump (PN GPA-4), which had a coordinated filter at the base of the pump. This filter will be supplemented with an in-line Holley filters.

LS motors, and EFI motors when all is said in done, have exceptionally specific fuel needs. It's anything but difficult to overcomplicate things, however we chosen to keep it basic. The principle player in our EFI fuel framework is this tank from Tanks Inc. (PN TM37B-T). It's inside perplexed and 1-inch more profound for expanded limit. The steel tank is electrifies and afterward powdercoated silver. The tank utilized Tank Inc's. high-flow (255-lph) submerged pump (PN GPA-4), which had a coordinated filter at the base of the pump. This filter will be supplemented with an in-line Holley filters. Alongside the pump we introduced the 0-90-ohm fuel level sender (PN TAN-GML) and after that began pipes and wiring the framework. The three ports are supply (from the pump), return (from the Holley 12-846 fuel controller), and vent line. For the hoses we utilized Earl's push-lock items on the grounds that they're anything but difficult to introduce and simple on the wallet. We mounted the Holley controller under the auto, back close to the tank.

Alongside the pump we introduced the 0-90-ohm fuel level sender (PN TAN-GML) and after that began pipes and wiring the framework. The three ports are supply (from the pump), return (from the Holley 12-846 fuel controller), and vent line. For the hoses we utilized Earl's push-lock items on the grounds that they're anything but difficult to introduce and simple on the wallet. We mounted the Holley controller under the auto, back close to the tank. We could have modified the Chevelle's three-speed shifter to work with the 4L60E Chevrolet Performance transmission, yet we found a less demanding, better alternative. What we ran with was this Lokar Performance Products floor-mount shifter (PN FMS64L60DL). To clean everything up we additionally utilized their rectangular shifter boot and ring (PN 70-FMB).

We could have modified the Chevelle's three-speed shifter to work with the 4L60E Chevrolet Performance transmission, yet we found a less demanding, better alternative. What we ran with was this Lokar Performance Products floor-mount shifter (PN FMS64L60DL). To clean everything up we additionally utilized their rectangular shifter boot and ring (PN 70-FMB). Also, here's our finished introduce. We loved the production line look it has and were cheerful that the motor fired up on the first attempt. After dumping the iron bigblock (with a TH400) in support of the aluminum LS3 (with the 4L65E) we thumped 266 pounds off the auto! The greater part of that weight fell off the front, and the auto is more adjusted with 53 percent of the weight on nose.

Also, here's our finished introduce. We loved the production line look it has and were cheerful that the motor fired up on the first attempt. After dumping the iron bigblock (with a TH400) in support of the aluminum LS3 (with the 4L65E) we thumped 266 pounds off the auto! The greater part of that weight fell off the front, and the auto is more adjusted with 53 percent of the weight on nose. The auto ran, however it was somewhat off, undoubtedly because of the cam swap. Along these lines, we drove it over to Westech Performance for some tuning on their Superflow skeleton dyno. In any case, our day was stopped when something turned out badl.

The auto ran, however it was somewhat off, undoubtedly because of the cam swap. Along these lines, we drove it over to Westech Performance for some tuning on their Superflow skeleton dyno. In any case, our day was stopped when something turned out badl. The stock driveshaft wound in half and decimated the floor and deplete framework. We talked with the folks over at Inland Empire Driveline and they thought it had more to do with the higher rpm of the new LS3 than with the force levels. The 3.5-inch aluminum shaft Inland Empire made for us will doubtlessly outlive the auto also, cost not as much as every one of the repairs we needed to make to the floor and debilitate framewer.

The stock driveshaft wound in half and decimated the floor and deplete framework. We talked with the folks over at Inland Empire Driveline and they thought it had more to do with the higher rpm of the new LS3 than with the force levels. The 3.5-inch aluminum shaft Inland Empire made for us will doubtlessly outlive the auto also, cost not as much as every one of the repairs we needed to make to the floor and debilitate framewer. With the Chevelle repaired, what's more, the new driveshaft introduced, we did a reversal to Westech to finish our dyno tuning session. The Chevy put down 416 strength and 407 lb-ft of torque to the back tires! Crest torque was around 5,700 rpm, however the control effectively conveyed to 6,000 rpm. Crest torque was at 4,700 rpm, yet even route down at 2,900 rpm it was ledge beating out 390 lb-ft. In the wake of driving the Chevelle around town for a couple weeks we additionally saw a colossal change in efficienc.

With the Chevelle repaired, what's more, the new driveshaft introduced, we did a reversal to Westech to finish our dyno tuning session. The Chevy put down 416 strength and 407 lb-ft of torque to the back tires! Crest torque was around 5,700 rpm, however the control effectively conveyed to 6,000 rpm. Crest torque was at 4,700 rpm, yet even route down at 2,900 rpm it was ledge beating out 390 lb-ft. In the wake of driving the Chevelle around town for a couple weeks we additionally saw a colossal change in efficienc.